Beyond the Grid: Manufacturing power for the next era of space – Kevin Hell, CEO

Featuring an interview with the leadership team at mPower Technology

Welcome back to Beyond the Grid, our ongoing Q&A series exploring how power shapes the future of space. In this edition, we go deep on one of the most fundamental constraints in the space economy: how you actually manufacture power at scale.

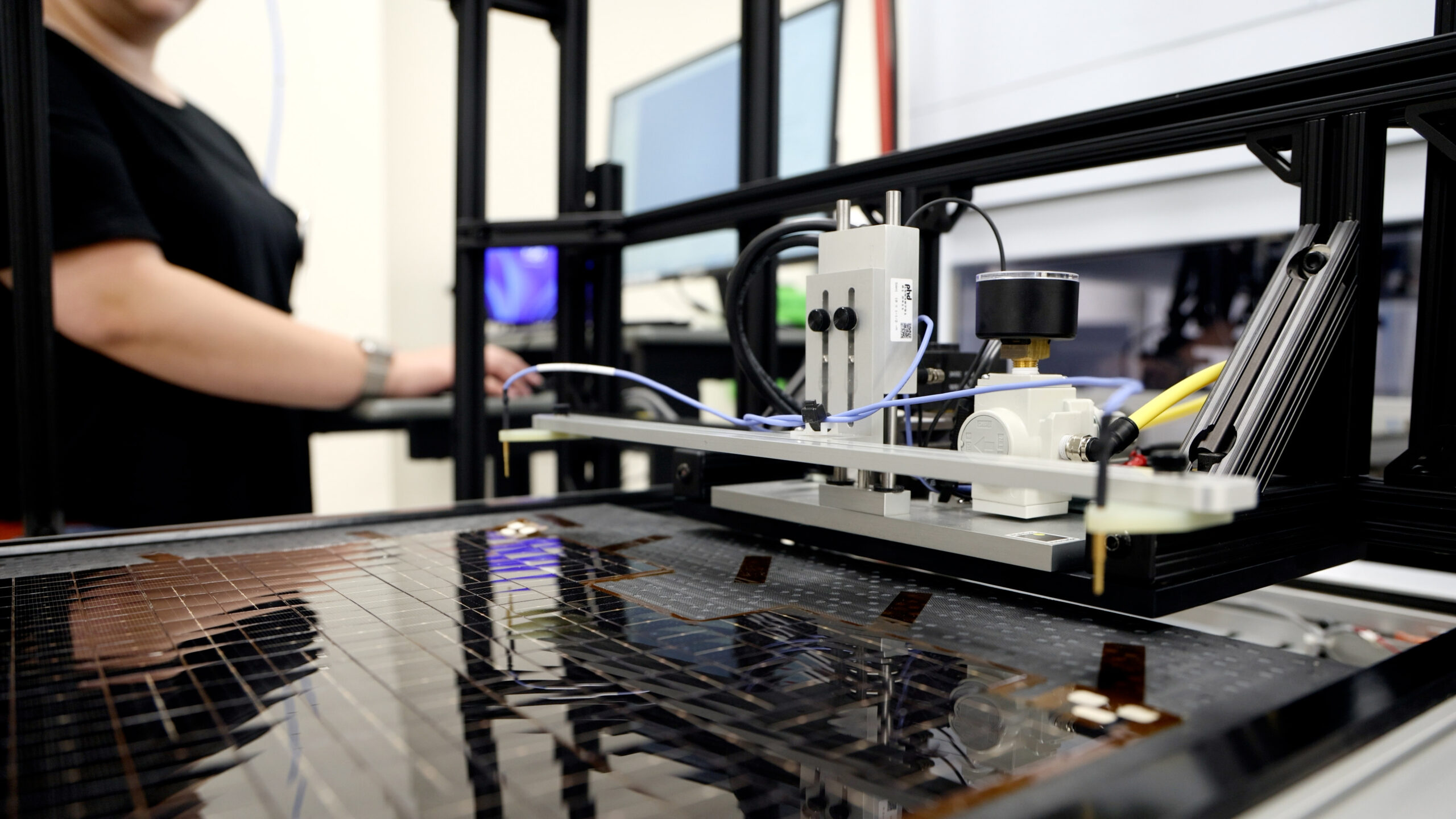

mPower Technology recently crossed a major threshold—launching the first automated, high-volume production line for space-grade solar modules. We spoke with CEO Kevin Hell about what comes next: scaling capacity, serving new mission types beyond LEO, competing in a rapidly changing market, and laying the groundwork for space as real infrastructure.

From prototype to production

Q: Your automated, high-volume production line is a big milestone. Over the next 12–18 months, how do you plan to scale manufacturing capacity—and what bottlenecks still exist?

We’re scaling our high-volume (HV) production line from 1 MW to 2 MW per year as we move into 2026. That growth comes from two levers: adding equipment to increase throughput within the same footprint, and staffing additional shifts by expanding our workforce.

The biggest bottleneck right now is optimization, fine-tuning manufacturing parameters to maximize yield and throughput. That’s normal at this stage, and it’s exactly where our focus is.

The other constraint is workforce development. We’re investing heavily in building a skilled manufacturing base at our New York facility, including partnerships with regional universities and intensive in-house training. Scaling space power isn’t just about machines, it’s about people who know how to run them.

What helps enormously is the inherent design of DragonSCALES. Its architecture allows near-endless customization (geometry, layout, voltage) without adding production complexity, which means we can support a wide range of missions without slowing the line down.

Powering more than satellites

Q: Space missions are expanding beyond LEO constellations into lunar, deep-space, logistics, mobility, and even space-based solar power. How does mPower position DragonSCALES across such diverse use cases?

DragonSCALES offers distinct advantages across nearly every emerging mission category. For lunar missions, the technology is lightweight, performs well in cold environments, and is flexible and resilient enough to support deployable and redeployable systems. Its scalability is especially important for future lunar habitats, manufacturing facilities, and mining operations that will require far more power than today’s satellites.

For space logistics and mobility missions, DragonSCALES provides voltage adjustability that is particularly valuable for electric propulsion systems, along with customized designs that can conform to nontraditional geometries, such as curved habitats or specialized vehicles. Its resilience to damage also makes it well-suited for dynamic, long-duration operations.

For space-based solar power, DragonSCALES enables large-scale deployments that are economically viable, modular by design, and capable of minimizing maintenance over time. Looking ahead to 2026, we expect the strongest growth beyond LEO to come from space logistics and mobility missions, while lunar infrastructure and space-based power systems are likely to follow on a slightly longer timeline.

Cost, scale, and competitive dynamics

Q: How do you see the competitive landscape evolving, particularly relative to gallium-arsenide solutions and new silicon-based alternatives?

Compared to established gallium-arsenide technologies, DragonSCALES delivers two decisive advantages: availability at scale and cost. The entire III-V industry produces only about 1.5 to 2 megawatts per year in total capacity, which means a single large LEO constellation can consume most or all of global supply. Scaling gallium-arsenide production is both technically difficult and extremely expensive, and gallium itself is becoming increasingly scarce due to global trade dynamics. Cost is the other major constraint—gallium-arsenide solutions are simply too expensive to support many of the next-generation Space 2.0 missions. DragonSCALES modules are approximately three to five times less expensive than equivalent III-V solutions.

Relative to newer silicon-based alternatives, DragonSCALES is significantly further along in terms of readiness and maturity. With more than fifteen years of flight heritage and an operational high-volume production line, mPower is years ahead of most emerging competitors. Beyond readiness, DragonSCALES offers unique benefits derived from its interconnected silicon architecture, including lighter weight, voltage adjustability, flexibility, customization, and resilience to damage. Like all silicon-based solutions, DragonSCALES also benefits from radiation recovery over time, a process that can be accelerated with temperature—an important advantage for long-duration missions.

Space as infrastructure, not just missions

Q: Over the next five to ten years, how does mPower envision its role within a broader space infrastructure ecosystem?

Over time, we see mPower evolving from a subcomponent supplier for satellites into a foundational enabling technology partner for the broader space economy. Our ambition is to support large-scale power solutions in space in much the same way that companies like Siemens, GE, Hitachi Energy, and Schneider Electric enable terrestrial power grids. That means providing the core technologies that make lunar power grids, space-based energy harvesting, power distribution systems, and heavy industrial activity in space possible.

We’re preparing for that shift by working closely with solution providers and system integrators across a range of emerging missions, including space power generation and beaming, space habitats, in-space manufacturing, ISRU, and orbital data processing and computing. The future of space will depend on reliable, scalable power infrastructure, and we intend to be a key enabler of that transition.

Scaling without stagnation

Q: As production volumes increase and demand accelerates, how is mPower ensuring reliability and innovation continue to advance?

A critical part of our strategy is leveraging the massive efficiency gains emerging from the terrestrial silicon market, which benefits from billions of dollars in global R&D investment. DragonSCALES is inherently cell-agnostic, allowing us to rapidly incorporate higher-efficiency cell technologies such as TOPCon, heterojunction cells, and eventually perovskite tandem cells as they become commercially viable. This flexibility ensures that DragonSCALES remains at the forefront of performance as the market evolves.

In parallel, we’re investing with partners to optimize panel layouts, solar array wings, and in-space power structures to minimize cost, weight, and stowage volume while improving modularity and deployment reliability. We’re also advancing work on radiation recovery and enabling high-voltage designs that reduce the need for complex power management electronics, particularly for electric propulsion systems. Together, these efforts ensure that as we scale, we continue to push performance, reliability, and innovation forward.

Power is rapidly becoming the limiting factor—and the unlocking force—of the next era of space. As missions grow larger, more complex, and more permanent, the ability to manufacture power systems at scale will determine what’s possible. mPower’s approach makes one thing clear: space power is no longer just a component problem—it’s an infrastructure challenge.

Stay tuned for more in Beyond the Grid, where we continue exploring how power is shaping the final frontier.